Industrial Users

Industrial users of ASCR facilities stimulate innovation, promote U.S. competitiveness, and help maximize the public benefit of ASCR facilities. ASCR facilities are open to industry through the ASCR Facilities access mechanisms. These access mechanisms enable innovation and expand the impact of HPC in industry by providing awardees with computing time and expert assistance in HPC pilot studies, proof-of-concept trials, and validation of simulations at scale. See below for industry success stories from ASCR facilities.

Building on past success and experience with industrial users, ASCR centers continue to promote and facilitate industrial access to ASCR facilities. Industry users of ASCR facilities often have unique requirements from university and national laboratory counterparts, including I.P considerations, proprietary codes, and different user support needs. Additionally ASCR facilities are at the cutting edge of multiple digital technologies and architectures. To help industry navigate the breadth of ASCR capabilities, each facility has established an Industrial User Point of Contact and recommended landing page for industrial users.

Contacts for Industry

OLCF Website for Industry

Suzy Tichenor

Director, Industrial Partnerships,

Computing and Computational Sciences

Oak Ridge National Laboratory

(703) 413-7846

[email protected]

NERSC Website for Industry

David Skinner

Strategic Partnerships Lead

NERSC

Lawrence Berkeley National Laboratory

(510) 486-4748

[email protected]

ALCF Website for Industry

David Martin

Industrial Outreach Lead

Argonne Leadership Computing Facility

Argonne National Laboratory

(603) 252-0929

[email protected]

ESnet Website for Testbed Access

Brian Tierney

Group Lead

ESnet

Lawrence Berkeley National Laboratory

[email protected]

Industry Features

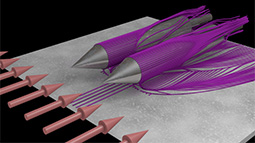

GE Researchers Perform Simulations in Pursuit of More Efficient Jet Engines and Wind Turbines

General Electric